I made the plastic drift even longer.

Finally got it out. Look at that rust(?) on the barrel.

Or glue? Maybe someone though the forearm was loose and tried to tack it in place?

It’s interesting rust.

The tube seems ok although dirty inside.

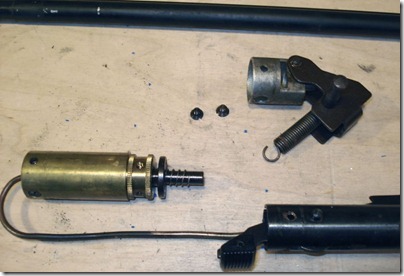

The piercing cap should come apart easily.

Ok, I can remove this.

Bent my much modified tool.

Finally unscrewed the top piercing pin. But I was unable to go further. The piercing cap pieces are stuck together. I’m soaking them and may need to apply heat. It’s not as bad as some guns I’ve taken apart but a few issues will need to be dealt with.