Removed the rear grip frame and rear breech bolts. The end cap and hammer spring pop right out.

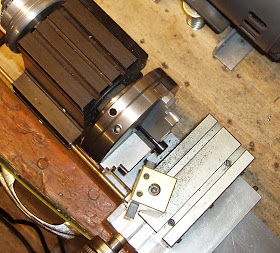

Chucked the end cap into the 3-jaw on the Taig lathe and spotted with a center drill.

I've got more metric blots lying around than SAE, so I though drilled with a #8 (0.1990") bit...

...and tapped the hole M6 x 1.0mm

Chucked an M6 socket head bolt...

...and turned the head down to fit inside the end of the hammer spring.

Like so.

Now I need an unobtrusive adjuster handle. A small M6 aluminum nut will do the trick.

I center punched a dimple into one of the flats and drilled through with a #43 (0.0890") bit.

Not shown: Tapped the hole with a 4-40 tap.

(don't forget to use cutting fluid when tapping threads)

Set screw installed in the nut. The M6 adjuster bolt is too long.

Eyeballed, guessed, and crossed my fingers for luck.

Pretty straightforward.

Spring was shortened by about 3 coils to make up for the length of the base on the M6 bolt.

The hammer spring isn't stock. Something I found in a box of springs that looked promising.

Snugged down the set screw then tightened the adjuster all the way in. Mounted it in the lathe and faced down the end of the nut and M6 bolt. Blued the end of the steel M6 bolt with my old standby, Brownell's 44/40.

Adjuster at about mid range.

Wanted enough speed to punch clean scoring holes in those heavy card stock Gamo targets. They seem to need about 385--400 fps to cut easy to score holes. Lower power will also increase shot count and decrease sound--good things for indoor use. With the adjuster full out, Crosman .177 cal wadcutters were clocking right around 435 fps. Turned fully in, the same pellet was averaging just over 550 fps.

Just a bit more speed than I truly need, but it's more than close enough to be in the ballpark. A slightly softer spring could be substituted if further refinement was necessary. I suppose it's also now possible to play with velocity and fine tune for a given pellet.