The Diana Modell 5 (The Blue Book calls it the Model V)

Stock screws are removed. I forget which side has the longer screws...not that I did at the time.

The trigger guard is unscrewed and unhooked from the action and then the stock can be removed. I'll call the grips "the stock" as it's made of wood...

The spring sits in the a hole in the stock, just as with the Slavia.

Notice the large amount of schmutz at the trigger.

The barrel was removed from the tube.

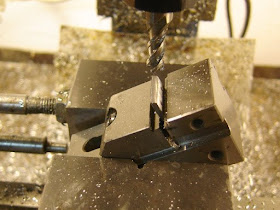

The barrel pivot screw was shimmed to time the cutouts with the lockscrew.

The llink is slid forward so that the pin can be pushed out of the enlarged opening.

A clever design of two diameters.

This is actually a shot of reassembly, the tiny pin is what the trigger guard hooks over. Don't lose it...

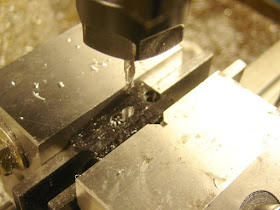

The trigger pin is pushed out.

The sear and pin.

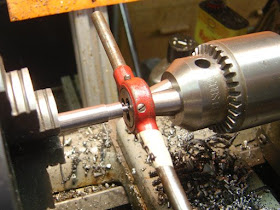

Just as with every other Diana pistol, I put it in the compressor and removed the end cap.

That's the amount of preload.

You can see a tiny setscrew to the left of the end cap. It keeps the cap from unscrewing but as far as I can tell doesn't bear against anything, just sits within the slot of the tube.

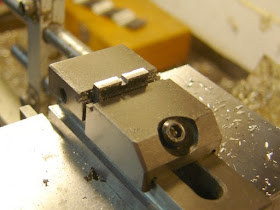

The piston with it's huge block. Notice the shaved bits of leather seal. The bit at the bottom was in the sear interface, likely what caused it to go off...

The piston seal itself was in fine shape. You can see the circuar groove in the attached block. I'm not sure how they attached that block to the piston.

I shaved off the fuzz from the piston. Then I lubed and reassembled in reverse order. The pistol now only goes off when the trigger is pulled. Which is a good thing.