This was my first attempt at making a rear sight. Apparently tempered blue shim steel does not like bending.

I printed up a sticky label with the sight laid out on it and sawed the shape.

Sawn out.

I centerpunched the hole locations.

Bent easily as it was annealed stock. Not sure what alloy as it was from my pile of random steel. I refined the shape with files.

Looks like a sight.

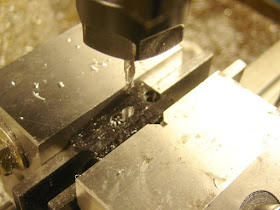

Finding the edge of the dovetail piece.

Drilling.

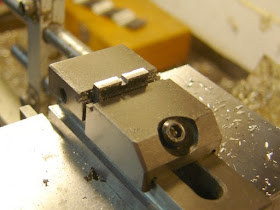

Milling to thickness.

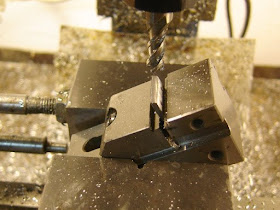

Felt tip marker applied to the edge.

Milling the dovetail. The angle seemed imprecise on the pistol...

I filed it to be a sliding fit.

Not full dovetail contact though, someone peened the slot earlier, most likely to avoid having the original sight slide out and become lost. They failed.

Tapping #2-64.

The parts attached with #2-64 screws. I wasn't going to spot weld it. I can live with it not being a perfect reproduction.

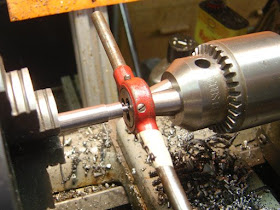

Turning the height adjustment screw.

Using the tailstock chuck jaws to align the die stock. I need to make a die holder for the South Bend...

Knurling.

All done. I heated it up cherry red and quenched, then tempered it for springiness. Then I cleaned it, cold blued all the parts and assembled.

Here's a shot of the Slavia ZVP with my Diana Modell 5. Neither of them are particularly accurate and the Diana gave me a surprise that I'll discuss later on...